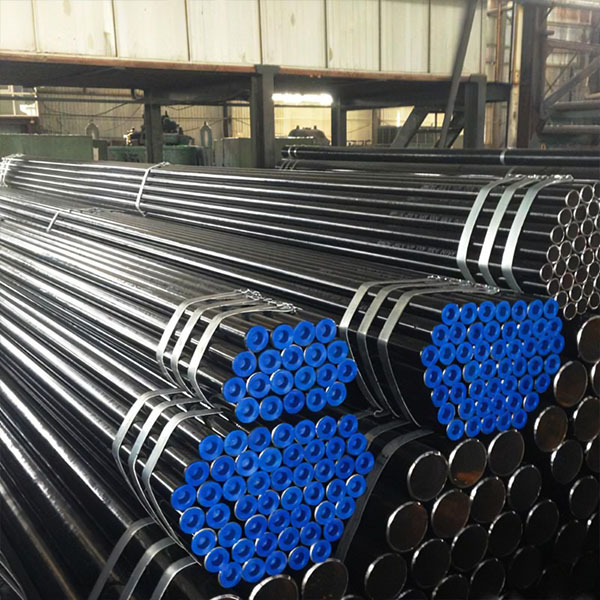

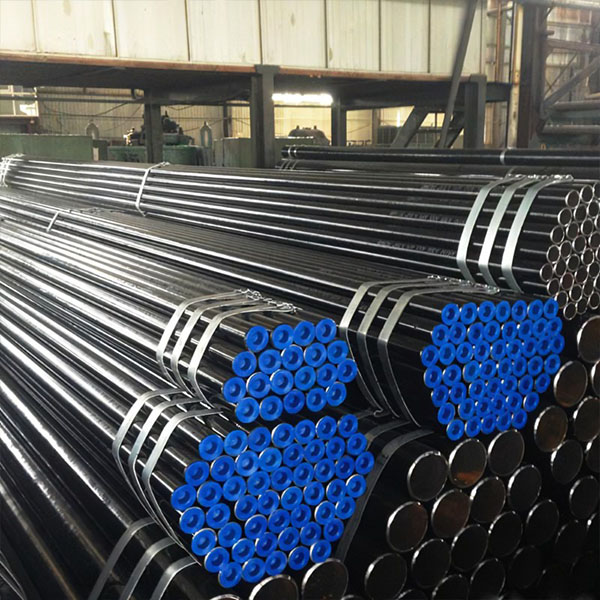

P91 Solid Alloy Tube

P91 alloy pombi maererano GB/T8162-87

4.1.Tsanangudzo: Iyo dhayamita yekunze yechubhu inopisa-yakatenderedzwa ndeye 32 ~ 630mm.Ukobvu hwemadziro ndeye 2.5 ~ 75mm.Iyo dhayamita yekunze yechando yakakungurutswa (inotonhora inodhonzwa) pombi ndeye 5 ~ 200mm.Ukobvu hwemadziro ndeye 2.5-12mm.

4.2.Unhu hwekuonekwa: mukati uye kunze kwekunze kwepombi yesimbi haifanirwe kuve nekutsemuka, kupeta, mipumburu, delamination, mitsetse yebvudzi uye mavanga mavanga.Kukanganisa uku kunofanirwa kubviswa zvachose, uye ukobvu hwemadziro uye dhayamita yekunze haifanire kudarika kutsauka kwakashata mushure mekubviswa.

Manufacturing nzira

Zvinoenderana neyakasiyana nzira dzekugadzira, inogona kukamurwa kuita inopisa-yakatenderedzwa machubhu, inotonhora-yakatenderedzwa machubhu, inotonhora-inodhonzwa machubhu, extruded chubhu, nezvimwe.

1.1.Anopisa akakungurutswa P91 alloy machubhu anowanzo gadzirwa pane otomatiki chubhu inotenderedza zvigayo.Iyo chubhu yakasimba inoongororwa uye kucheneswa kwehurema hwepamusoro, inochekwa kusvika paurefu hunodiwa, yakanangidzirwa pamucheto wechubhu ine perforated, yozotumirwa kuchoto chekudziya kuti ichidziswe uye kubaiwa pamushini wekuboora.Kana iyo perforation ichiramba ichitenderera uye ichifambira mberi panguva imwe chete, pasi pechiito che roller uye plug, mhango inoumbwa zvishoma nezvishoma mukati mechubhu isina chinhu, iyo inonzi capillary tube.Uye wozotumirwa kune automatic rolling mill kuti uenderere mberi nekukunguruka.Chekupedzisira, ukobvu hwese hwemadziro hwakashongedzwa nemuchina wekuenzanisa, uye dhayamita iri kuyerwa nemuchina wekuyera kuti usangane nezvinodiwa.Iyo inzira yepamusoro yekugadzira inopisa-yakakungurutswa P91 alloy pombi uchishandisa inoenderera pombi inotenderedza mills.

1.2.Kana iwe uchida kuwana mapombi asina musono ane saizi diki uye mhando iri nani, inotonhorera inotenderedza, inotonhora kudhirowa, kana musanganiswa wenzira mbiri idzi dzinofanirwa kushandiswa.Cold rolling inowanzoitwa pachigayo chepamusoro-chepamusoro.Iyo pombi yesimbi inokungurutswa mu annular pass yakaumbwa neinochinja-chinja-chikamu denderedzwa gomba groove uye yakamira tapered plug.Kudhirowa kutonhora kunowanzoitwa pane imwe-cheni kana mbiri-cheni inotonhora yekudhirowa muchina we0.5 kusvika 100T.

1.3.The extrusion nzira ndeyokuisa inopisa chubhu blank muvharika extrusion humburumbira, uye perforated tsvimbo uye extrusion tsvimbo kufamba pamwe extruded extruded chikamu kubva diki kufa gomba.Iyi nzira inogona kugadzira mapaipi esimbi ane madhayamita madiki.

2.1.P91 alloy chubhu ine huwandu hwakawanda hwekushandisa.Iyo general-chinangwa P91 alloy pombi inokungurutswa kubva kune yakajairwa kabhoni structural simbi, yakaderera-alloy dhizaini simbi kana alloy chimiro chesimbi, uye ine yakakura kubuda.Inonyanya kushandiswa semapaipi kana zvikamu zvezvimiro zvekufambisa mvura.

2.2.Maererano nezvinangwa zvakasiyana, yakakamurwa kuva marudzi matatu ekupa: a.Maererano nemakemikari ekuumbwa uye mechanical properties;b.Zvinoenderana nema mechanical properties;c.Maererano ne hydraulic test.Mapombi esimbi anopihwa zvinoenderana nezvikamu a uye b, kana akashandiswa kumirisana nedzvinyiriro yemvura, anozoiswawo mukuyedzwa kwehydraulic.

2.3.P91 alloy mapaipi ezvinangwa zvakakosha anosanganisira P91 alloy mapaipi emaboilers, P91 alloy mapaipi ejiology uye mapaipi asina musono epetroleum.

Zvinhu zvikuru zvealloying zvealloy pombi isilicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminium, mhangura, boron, isingawanzo pasi, etc. shoma shoma inodiwa Pamusoro pekudzivisa silicon, manganese, phosphorus, uye sarufa, inewo humwe huwandu hwealloying elements.Iyo alloying elements musimbi zvinosanganisira silicon, manganese, molybdenum, nickel, sulfur, vanadium, titanium, niobium, boron. , lead, rare earths, etc. Imwe kana mamwe marudzi esimbi anonzi alloy steels.Iyo alloy simbi masisitimu inosiyana neyakasiyana zviwanikwa mamiriro, kugadzirwa uye mamiriro ekushandisa.Munguva yakapfuura, nickel nesimbi masisitimu akagadzirwa kune dzimwe nyika.China yakaona kuti silicon, manganese, Vanadium, titanium, niobium, boron, lead, uye isingawanzo pasi alloy steel system alloy simbi inokwana chikamu gumi kubva muzana chekubuda kwesimbi.Kazhinji, alloy simbi mapaipi anogona kukamurwa kuva 8 makuru marudzi maererano nekushandisa kwavo.Mhando, ndeidzi: alloy structural simbi mapaipi, chitubu simbi pombi, ane simbi pombi, alloy mudziyo simbi pombi, high-speed mudziyo simbi pombi, Stainless simbi pombi, kupisa-anopikisa asiri-ganda simbi pombi, magetsi silikoni simbi pombi PC/ABS. kuve nechimiro chakanaka uye chinogona kugadzirisirwa mota hombe Zvikamu, senge mota fenders, zvine mutengo wakakwira kuita.Mapaipi esimbi alloy anogadzirwa neakajairwa kabhoni simbi nekuwedzera huwandu hwakakodzera hwechimwe kana anopfuura alloying zvinhu kune kupatsanurwa kwesimbi-carbon alloy simbi mapaipi: mapaipi esimbi akakamurwa kuita P91 alloy pombi uye welding Simbi pombi zvichingodaro.