Welded Square Tube

yakagadzirwa muChina

Kushandisa: boiler chubhu,

Kunyangwe iyo pombi yakabatana nealloy: isiri-alloy

Sectional chimiro: square

Special chubhu: API

Tube ukobvu: 1.5-60

Kurapa kwepamusoro: pendi yakasviba

Kushivirira: ± 1%

Masevhisi ekugadzirisa: kukotama, welding, kubaya, kucheka

zvinhu: Q195/Q215/Q235/Q345/10#/20#

Surface: dema pfapfaidzo pendi

Chimiro: square tube

Packing: standard packing

Keywords: musono simbi pombi

Delivery nguva: 7-15 mazuva

Inner shape simbi pombi: black hollow chikamu

Minimum odha huwandu: 1 ton

Chinangwa: Kuvaka chimiro

Technology: Hot Rolling

Authentication: API

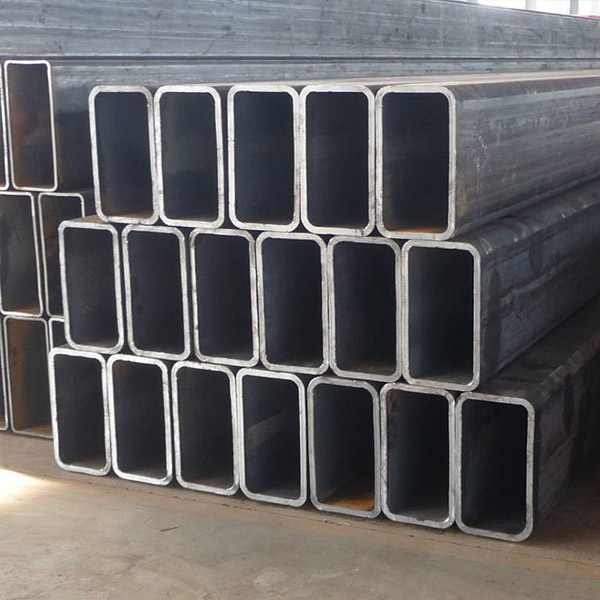

1. Welded square chubhu ihollow square section steel square chubhu, inozivikanwawo sehollow cold-formed steel. Iyo inogadzirwa neinotonhora kukotama uye yakakwirira-frequency welding mushure mekupisa-yakakungurutswa kana kutonhora-yakakungurutswa tambo kana coil seyakashama Yakaumbwa simbi ine sikweya-chikamu chechikamu chimiro uye saizi.

Pamusoro pekukora kwemadziro ehukobvu-walled square chubhu, ukuru hwekona uye kumucheto flatness inosvika kana kudarika mwero wekupikisa welded cold-formed square chubhu. Saizi yeR angle inowanzova pakati pe2 nguva uye 3 nguva ukobvu hwemadziro. .Maererano nezvinodiwa nevatengi, tinogonawo kugadzira R-angle square tubes yehukuru hunodiwa nevatengi;

2. Square chubhu Seamless square chubhu isimbi yakareba tambo ine mhango chikamu uye isina majoini painotenderera. Ichubhu yeskweya inogadzirwa nekuburitsa chubhu isina musono kuburikidza nemativi mana eforoma. Iyo square chubhu ine mhango chikamu uye inoshandiswa muhuwandu hukuru. Inoshandiswa mukufambisa kwemvura, hydraulic tsigiro, dhizaini chimiro, yepakati uye yakaderera kudzvanywa, yakanyanya kumanikidza boiler chubhu, kupisa kupisa chubhu, gasi, peturu uye mamwe maindasitiri. Iyo yakasimba kudarika welded uye haizotsemuka.

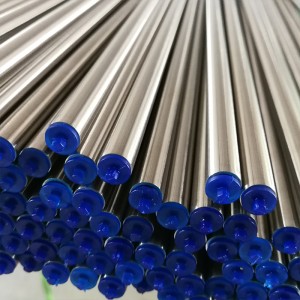

1. Maitiro ekuyerera kwehutsanana girazi chubhu:

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling Passivation-inspection-cold rolling-degreasing-kucheka-air drying-internal polishing -kunze kupenya-kuongorora-kumaka-kupedza chigadzirwa kurongedza.

2. Industrial pipe process

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling Passivation-inspection.

3. Maitiro ekuyerera kwe welded pombi

Kusunungura-leveling-kuguma kugera uye welding-looper-forming-welding-yemukati uye yekunze bead kubviswa-pre-correction-induction heat treatment-size uye straightening-eddy current test-cut---Hydraulic pressure inspection——Pickling——Kuongorora kwekupedzisira ——Kurongedza.

4. Seamless square tube process

Round steel-tube billet-inspection-heating-kuboora-size-hot rolling-flat head-inspection-pickling-spherical annealing-inotonhora drawing-forming-Qikou- -test

Q345A:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345B:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345C:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.030,Al≥0.015;

Q345D:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.025,Al≥0.015;

Q345E:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.025,S≤0.020,Al≥0.015;

Q345A, B, C, D, E Nb≤0.07,V≤0.15,Ti≤0.20,Cr≤0.30,N≤0.012,Mo≤0.10. 20#, Q235B

| Gobvu-yakakomberedzwa sikweya pombi yakatarwa tafura (mm) | Tafura yakakora-yakakomberedzwa nerectangular pombi (mm) | ||

| 16~34×0.4~2.0 | 380~500×380~500×8.0~30.0 | 10~20×20~40×0.6~12.0 | 250~300×100~250×6~30.0 |

| 16~34×0.4~2.0 | Imwe tsananguro yedraw ndeiyi inotevera | 20×50×1.0~2.0 | 400×250×8~30.0 |

| 38×38×1.0~4.0 | 550×550×10.0~40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50×60×2.0~5.0 | Imwe tsananguro yedraw ndeiyi inotevera | |

| 120~350×120~350×4.0~30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |