Yakagadzirwa Alloy Steel Plate

Iyo checkered plate ine zvakawanda zvinobatsira zvakadai seyakanaka kutaridzika, anti-skid, kusimbisa kushanda, kuchengetedza simbi nezvimwe zvakadaro. Inoshandiswa zvakanyanya mukufambisa, kuvaka, kushongedzwa, pasi yakatenderedza midziyo, michina, kuvaka ngarava nemimwe minda. Kazhinji kutaura, mushandisi haana zvakakwirira zvinodikanwa pamichini yezvivakwa uye mechanical zvimiro zvecheckered plate, saka kunaka kwecheckered plate kunonyanya kuratidzwa muyero yekugadzira maitiro, urefu hwepateni, uye mutsauko wehurefu hwepateni. Ukobvu hwakajairwa pamusika hunobva pa2.0-8mm, uye hupamhi hwakajairika i1250 ne1500mm.

Classification by ukobvu

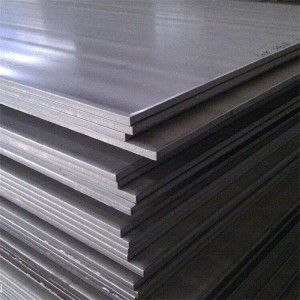

Simbi ndiro yakatetepa <4 mm (iyo yakaonda kupfuura 0.2 mm), gobvu simbi ndiro 4-60 mm, yakawedzera-yakakora simbi ndiro 60-115 mm. Iyo yakafara yeplate yakaonda ndeye 500-1500 mm; hupamhi hwendiro yakakora ndeye 600-3000 mm. Rudzi rwesimbi rwesimbi gobvu ndiro Iyo inonyanya kufanana nesimbi yakatetepa ndiro. Panyaya yezvigadzirwa, mukuwedzera kune bhiriji simbi mahwendefa, boiler simbi mahwendefa, mota yekugadzira simbi mahwendefa, kumanikidza mudziyo simbi mahwendefa uye akawanda-layer-yakakwirira-kudzvanya midziyo simbi mahwendefa, ayo ari mahwendefa akakora, mamwe marudzi emarata esimbi senge mota. simbi simbi mahwendefa (ukobvu 2.5-10 mm), pateni Simbi mahwendefa (ukobvu 2.5-8 mm), Stainless simbi ndiro, simbi inodzivirira kupisa, nezvimwewo zvinoyambutswa nemahwendefa matete. 2. Simbi yesimbi yakakamurwa kuva inopisa-yakaputirwa uye inotonhora-inoputika maererano nekukunguruka.

Inorongwa nechinangwa

(1) Bhiriji simbi ndiro (2) Boiler simbi ndiro (3) Chikepe chesimbi ndiro (4) Armor steel plate (5) Motokari simbi ndiro (6) Roof simbi ndiro (7) Structural simbi ndiro (8) Electrical simbi ndiro (silicon simbi sheet) (9) Chitubu simbi ndiro ( 10) Zvimwe

Inokamurwa nechimiro

1. Simbi ndiro yekumanikidza mudziyo: Shandisa capital R kuratidza pakupera kwegiredhi. Giredhi rinogona kuratidzwa negoho poindi kana kabhoni yemukati kana alloying zvinhu. Zvakadai se: Q345R, Q345 ndiyo poindi yegoho. Mumwe muenzaniso: 20R, 16MnR, 15MnVR, 15MnVNR, 8MnMoNbR, MnNiMoNbR, 15CrMoR, nezvimwewo zvinomiririrwa nekabhoni yemukati kana alloying zvinhu.

2. Steel plate ye welding gasi cylinders: Shandisa capital HP kuratidza pakupera kwegiredhi, uye giredhi rayo rinogona kuratidzwa negoho point, senge: Q295HP, Q345HP; inogona zvakare kuratidzwa nealloying zvinhu, senge: 16MnREHP.

3. Simbi ndiro yeboiler: Shandisa mavara madiki g kuratidza panoperera zita rechiratidzo. Giredhi rayo rinogona kuratidzwa negoho point, senge: Q390g; inogona zvakare kuratidzwa nekabhoni yemukati kana alloying zvinhu, senge 20g, 22Mng, 15CrMog, 16Mng, 19Mng, 13MnNiCrMoNbg, 12Cr1MoVg, nezvimwe.

4. Mahwendefa esimbi emabhiriji: Shandisa mavara maduku q kuratidza pamagumo egiredhi, zvakadai seQ420q, 16Mnq, 14MnNbq, nezvimwewo.

5. Steel plate yemotokari yemotokari: Shandisa guru L kuratidza pamagumo egiredhi, zvakadai se09MnREL, 06TiL, 08TiL, 10TiL, 09SiVL, 16MnL, 16MnREL, nezvimwewo.

| Theoretical huremu tafura yecheckered simbi ndiro(mm) | ||||

| Basic ukobvu | Kutsauka kunobvumirwa kwehukuru hwekutanga | Theoretical mass (kg/m²) | ||

| Diamond | Nyemba | Round beans | ||

| 2.5 | ±0.3 | 21.6 | 21.3 | 21.1 |

| 3.O | ±O.3 | 25.6 | 24.4 | 24.3 |

| 3.5 | 土0.3 | 29.5 | 28.4 | 28.3 |

| 4.O | ±O.4 | 33.4 | 32.4 | 32.3 |

| 4.5 | ±O.4 | 38.6 | 38.3 | 36.2 |

| 5.O | +O.4 | 42.3 | 40.5 | 40.2 |

| -O.5 | ||||

| 5.5 | +O.4 | 46.2 | 44.3 | 44.1 |

| -O.5 | ||||

| 6 | +O.5 | 50.1 | 48.4 | 48.1 |

| -O.6 | ||||

| 7 | 0.6 | 59 | 58 | 52.4 |

| -O.7 | ||||

| 8 | +O.6 | 66.8 | 65.8 | 56.2 |

| -O.8 | ||||

| Cherechedza: | ||||

| 1. Kureba kwesimbi ndiro 600~1800mm, uye giredhi iri 50mm; kureba i2000 ~ 12000mm, uye giredhi i100mm. | ||||

| 2. Kureba kwemuenzaniso hakusi pasi pe 0.2 nguva yehupamhi hwe substrate. Saizi iri mumufananidzo haishandiswe sehwaro hwekupedzwa kwekuongorora kwechigadzirwa. | ||||

| 3. Zvikamu zvesimbi zvemahwendefa esimbi zvinoenderana neGB/T700, GB/T712, uye GB/T4171. | ||||

| 4. Iyo mechanical properties yesimbi mahwendefa haina kuvimbiswa. Kana mutengi aine zvinodiwa, zvinogona kubvumirana nemapato ese ari maviri zvinoenderana nematanho akakodzera. | ||||

| 5. Iyo ndiro yesimbi inounzwa munzvimbo inopisa yakaputirwa. | ||||

Zvinoenderana neyakajairwa yenyika GB/T 3277 yemaplateti esimbi ane patterned, kureba kwepateni kunofanirwa kunge kwakakura kudarika kana kuenzana ne20% yehukobvu hwe substrate.