Ordinary Flat Steel

Chikamu chesimbi ndeimwe yemhando ina huru dzesimbi (ndiro, chubhu, mbiri, waya). Maererano nechimiro chechikamu, chikamu chesimbi chakakamurwa kuva nyore chikamu chikamu simbi uye yakaoma chikamu chikamu simbi (chikamu chesimbi). Iyo yekutanga inoreva sikweya simbi, yakatenderera simbi, simbi yakati sandara, makona simbi, simbi ine hexagonal, zvichingodaro; iyo yekupedzisira inoreva I-beam, chiteshi simbi, simbi njanji, hwindo furemu simbi, simbi yakakomberedzwa, nezvimwe.

Galvanized flat simbi inogona kushandiswa kugadzira hoop irons, maturusi uye mekiniki zvikamu sechinhu chakapedzwa, uye inoshandiswa seimba yemapuranga ezvimiro zvikamu uye escalator mukuvaka.

Galvanizing process

Kupisa-dip galvanizing kunonziwo hot-dip galvanizing uye hot-dip galvanizing: inzira inoshanda yesimbi inorwisa ngura, inonyanya kushandiswa muzvivakwa zvesimbi mumaindasitiri akasiyana siyana. Zvikamu zvesimbi zvakasvibiswa zvakanyungudutswa mune yakanyungudutswa zinc solution inenge inenge 500 ° C, kuitira kuti zinc layer inosungirirwa pamusoro pezvikamu zvesimbi, zvichiita kuti zvibudirire chinangwa chekudzivirira-corrosion.

Kupisa-dip galvanizing process: yapera chigadzirwa kunhonga-mvura yekugeza-inowedzera yebetsero plating mhinduro-kuomesa-rack plating-kutonhora-mushonga-kuchenesa-kupukuta-kupisa-dip galvanizing kupera

Kupisa-dip galvanizing kunogadzirwa kubva kune yekare hot-dip nzira. Iine nhoroondo yemakore 140 kubvira France yakashandisa galvanizing inopisa-dip kuindasitiri muna 1836. Zvisinei, indasitiri yokupisa inopisa-dip galvanizing yakagadziridzwa pamwero mukuru nekuvandudzwa nokukurumidza kwesimbi inotonhora yakakungurutswa mumakore 30 apfuura.

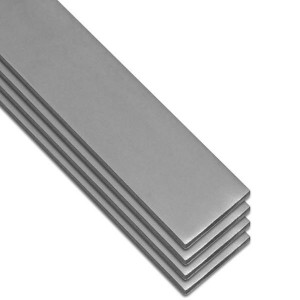

1. Izvo zvinyorwa zvechigadzirwa zvakakosha. Ukobvu 8-50mm, hupamhi 150-625mm, kureba 5-15m, uye zvigadzirwa zvakati dense, izvo zvinogona kusangana nezvinodiwa nevashandisi. Inogona kushandiswa panzvimbo yeplate yepakati uye inogona kuiswa zvakananga pasina kucheka.

2. Pamusoro pechigadzirwa chacho chakatsetseka uye chakachena. Iyo yakakwirira-inodzvinyirira mvura yekudzikisa nzira inoshandiswa kaviri mukuita kuti ive nechokwadi chekuti pamusoro pesimbi inotsvedza uye yakachena.

3. Mativi acho akamira uye chestnuts yemvura yakajeka. Yechipiri vertical rolling mukupedzisa kutenderera inovimbisa kumira zvakanaka pamativi ese, makona akajeka, uye kunaka kwepamusoro pamativi.

4. Chiyero chechigadzirwa chakarurama, mutsauko wezvikamu zvitatu, mutsauko wakafanana wepamusoro uri nani pane chiyero cheplate yesimbi; chigadzirwa chakatwasuka uye chimiro cheplate chakanaka. Iyo yekupedzisa rolling inotora iyo inoenderera mberi yekukunguruka, otomatiki looper otomatiki control, kuve nechokwadi chekuti hapana simbi yakaturikidzana kana kutambanudzwa, iyo chigadzirwa dimensional kurongeka kwakakwira, kushivirira renji, matatu-mapoinzi mutsauko, yakafanana mutsara musiyano, jeko bend uye mamwe ma paramita ari. zviri nani kupfuura ndiro yepakati, uye chimiro cheplate chakatwasuka. Degree rakanaka. Cold shearing, high precision yekureba saizi.

5. Chigadzirwa chacho chinotora mitemo yenyika, iyo yakafanana nematareti esimbi. Hunhu uye tekinoroji zviyero zvakarongwa zvinoenderana neYB/T4212-2010 zviyero (Q345B/Q235B inoreva GB/T1591-94 uye GB/T700-88 zviyero zvakateerana).

1. Kusimba kwepamusoro, chimiro chechiedza: iyo yakasimba grid pressure pressure welding structure inoita kuti ive neunhu hwekubereka kwepamusoro, chimiro chechiedza uye kusimudza nyore;

2. Chitarisiko chakanaka uye kusimba.

Precision flat flat simbi yekugadzira process Iyo yekushanda yeaflat simbi yekupedzisa muchina ndeye kushandisa maviri seti akadzedzereka kumusoro nekudzika mavhiri ekuyera kusvika ku-pre-level uye yekupedzisira nhanho ukobvu hwekutungamira kweinotonhora flat simbi simbi; shandisa peya yekupesana yakarongedzwa kupedzisa Mavhiri anodzvanywa muhupamhi kutungamira kuitira kuti hupamhi hunomanikidzwa kuti hubudirire zvinotarisirwa paramita, uye huwandu hwekumanikidza hunogadziriswa; shandisa mavhiri 5 akadzedzereka kutwasanudza hupamhi. Iyi sisitimu inonyanya kuumbwa nebhokisi rekutonga, roller yekupedzisa, pre-leveling unit, yekupedzisa unit, uye yekururamisa unit.

Maitiro ekugadzira anogona kupfupikiswa se: pre-leveling → kupedzisa → kutwasanudza → post-leveling. Flat steel/a/b isimbi ine hupamhi hwe12-300mm, ukobvu hwe4-60mm, rectangular cross-section uye micheto yakachena zvishoma. Simbi yakatsetseka inogona kunge yakapedzwa simbi chigadzirwa, kana inogona kushandiswa sebillet yemapombi akasungwa uye matete akatetepa emapepa akaturikidzana. Main application: Flat simbi inogona kushandiswa kugadzira hoop simbi, maturusi uye mekiniki zvikamu sechinhu chakapedzwa, uye inoshandiswa senge yekuvaka furemu chimiro uye escalator mukuvaka. Simbi yakatsetseka yakakamurwa kuita mhando mbiri zvichienderana nechimiro chayo: flat spring flat simbi uye single-sided double groove spring flat simbi. Kupisa-yakatenderedzwa chitubu chakafuratira simbi inonyanya kushandiswa kugadzira mashizha zvitubu zvemotokari, matirakita, njanji yekufambisa uye mimwe michina.

Process nzira yechirimo flat simbi yemotokari

Chitubu chakafuratira simbi inogadzirwa neinoshandura smelting process. Kuenzaniswa neiyo tekinoroji iripo, ine zvinotevera zvakanakira uye zvakanaka mhedzisiro:

1. Flat simbi inonyunguduka mushanduri inonyanya kushandisa simbi yakanyungudutswa seyakasvibirira, iyo ine zvishoma zvinokuvadza zvinhu musimbi yakanyungudutswa, uye kunaka kweiyo inogadzirwa simbi yakatsetseka inovimbiswa.

2. Pamusana pezvibereko zvakakwirira uye kushandiswa kwesimba shoma, mari yetani yakaderera pane yehuni dzemagetsi.

3. Simbi yakanyungudutswa inokandwa zvakananga mumabhiriji, iyo inobvisa nzira yekubhadhara uye inoderedza mari.

4. Iyo inoenderera ichikanda billet ine yakakwirira yekucheka-kusvika-kureba chiyero, iyo inogona kuvimbisa flat-simbi yekucheka-kusvika-kureba chiyero uye inosangana nezvinodiwa nevashandisi.