1. Pfeka-inodzivirira simbi ndiro overview

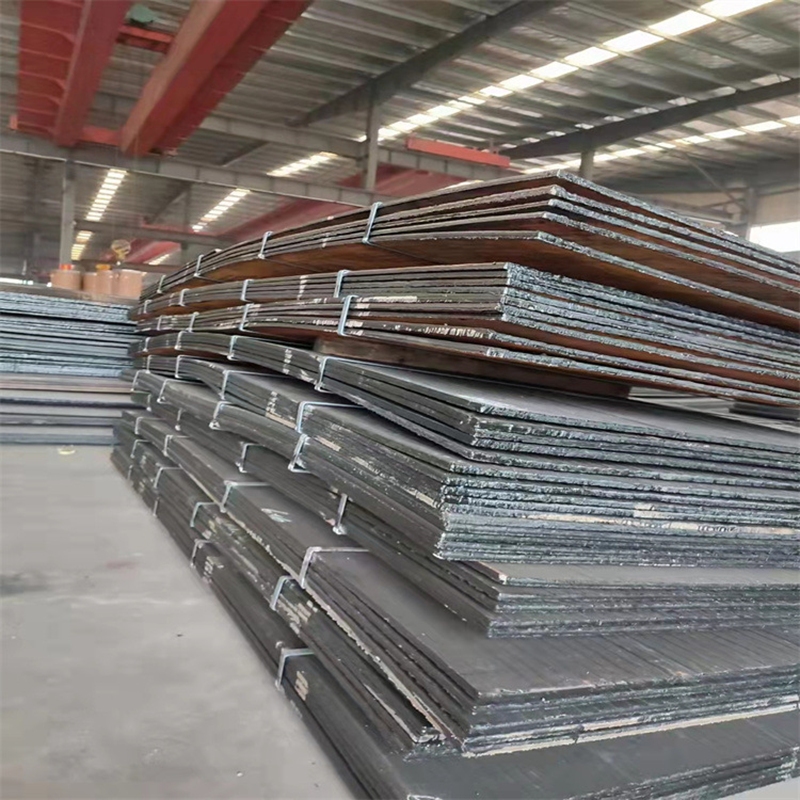

Pfeka Resistant Steel Plate, kureva kupfeka-resistant simbi ndiro, chinhu chakakosha cheplate chigadzirwa chinoshandiswa zvakanyanya pasi penzvimbo yakakura-yenzvimbo yekupfeka mamiriro ekushanda. Iyo inoumbwa neyakaderera-kabhoni simbi ndiro uye alloy kupfeka-resistant layer.

Kupfeka-resistant simbi ndiro ine hunhu hwekusimba kwepamusoro uye yakakwirira kupfeka kuramba. Iyo alloy kupfeka-inodzivirira layer inowanzo 1/3 kusvika 1/2 yehupamhi hwese. Kana iri pabasa, iyo matrix inopa yakazara zvimiro senge simba, kuomarara uye plastiki kurwisa masimba ekunze, uye alloy kupfeka-resistant layer inopa kupfeka kuramba kuzadzisa zvinodiwa zveakatsanangurwa mamiriro ekushanda.

Kune marudzi akati wandei emarata esimbi asingapfeki, anosanganisira mahwendefa esimbi anoumbwa nemubatanidzwa uye alloy akadzima anodzimwa-resistant steel plates. Semuyenzaniso, KN60 kupfeka-resistant simbi ndiro imhando yechigadzirwa chakagadzirwa nekubatanidza imwe gobvu yealloy kupfeka-resistant layer ine kuomarara kwakanyanya uye yakanakisa kupfeka kuramba pamusoro peyakajairwa low-carbon simbi kana yakaderera-alloy simbi nekusimba kwakanaka. uye plasticity kuburikidza nepamusoro nzira. Iyo tekinoroji parameters yeKN60 kupfeka-resistant steel plate ndeaya anotevera: the Vickers hardness is 1700HV; zvinhu zvacho zvakaderera-kabhoni simbi base, uye mamwe marudzi epamusoro akaomeswa alloys uye niobium carbide anogona kupihwa zvinoenderana nezvinodiwa. Iyo chromium uye boron alloy carbides dzakapfuma; kuoma kweiyo composite kupfeka-resistant layer ndeye C62-65 HRc; ukobvu ndeye 3 - 15 millimeters; iyo yakaoma alloy content inopfuura 50%; tembiricha yepamusoro yekushanda i1000°C.

Mukuwedzera, kupfeka-resistant simbi ndiro 360 zvakare imhando yepamusoro-yakasimba uye yakakwirira-kupfeka-inodzivirira kupfeka-inodzivirira ndiro. Iyo inogadzirwa ne prestressing tekinoroji uye ine zvirinani tensile simba uye compression simba, pamwe nekunaka kupfeka kuramba uye kukanganisa kuramba.

2. Zvishandiso zvemarata esimbi asingapfeki

2.1 Yakasiyana-siyana yekushandiswa kwemaindasitiri

Mahwendefa esimbi asingapfeki anowana kushandiswa kwakakura mumaindasitiri akasiyana. Muindasitiri yemetallurgical, anoshandiswa mumidziyo yakadai semacrusher uye mabhandi ekutakura, ayo anogara achiiswa pasi peabrasion uye kukanganisa. Muindasitiri yemarasha, vanoshandirwa mumarasha chute uye zvikamu zvemichina yemigodhi kuti vamire mumamiriro ezvinhu akaomarara. Indasitiri yesimende inoshandisa simbi isingapfeki muchoto uye zvigayo kuti ive nechokwadi chehupenyu hurefu. Muindasitiri yemagetsi, anoshandiswa mumarasha pulverizers uye madota ekubata masisitimu.

Semuyenzaniso, kupfeka-inodzivirira simbi ndiro 360 inoshandiswa zvakanyanya muminda senge mota, njanji, ndege, simbi, indasitiri yemakemikari, michina, peturu, magetsi, kuchengetedza mvura, uye kuvaka. Yakanakira zvinhu zvinotakura mitoro mikuru mumichina yemaindasitiri nekuda kwekunaka kwayo kupfeka kuramba, kupikisa kwemaitiro, uye kushomeka kwemarara.

2.2 Kudhura kwakanyanya-kushanda

Zvichienzaniswa nezvimwe zvinhu, mahwendefa esimbi asingapfeki anopa mutengo wakanyanya-kuita. Kunyangwe iyo yekutanga mutengo wemarata esimbi asingapfeki ungave wakakwira zvishoma pane zvimwe zvechinyakare, kusamira kwavo kwepamusoro uye kusimba kunoguma nekuchengetedza kwakakosha mukufamba kwenguva. Semuyenzaniso, kambani inoshandisa kupfeka-resistant simbi mahwendefa mukugadzira kwayo inogona kuwana yakadzikira nguva yekugadziriswa kwemidziyo nekutsiviwa, zvichikonzera kuwedzera kubereka uye kuchengetedza mutengo.

Zvinoenderana nedata, hupenyu hwesevhisi hwemarata esimbi asingapfeki hunowanzo kureba kakati wandei kupfuura yeakajairika mahwendefa esimbi. Izvi zvinoreva kuti makambani anogona kuderedza mari yavo yezvinhu uye mari yekugadzirisa nekufamba kwenguva. Pamusoro pezvo, kuita kwakanakisa kwemaplateti esimbi asingapfeki kunoderedza njodzi yekutadza kwemidziyo uye kunonoka kugadzira, zvichiwedzera kusimudzira kwavo hupfumi. Nekuda kweizvozvo, maindasitiri mazhinji uye vagadziri vari kuratidza kufarira mahwendefa esimbi asingapfeki.

3. Material classification yekupfeka-resistant steel plates

3.1 Common zvinhu mhando

Marata esimbi asingapfeki anowanzo gadzirwa nekuisa akaturikidzana alloy kusagadzika pamusoro peakajairika low-carbon simbi kana yakaderera-alloy simbi. Kune zvakare akakandwa mahwendefa esimbi asingapfeke uye alloy akadzima kupfeka-resistant simbi ndiro. Semuyenzaniso, iyo composite kupfeka-resistant simbi ndiro inogadzirwa nekubatanidza imwe gobvu yealloy kupfeka-resistant layer nekuomarara kwepamusoro uye nekupokana kwekupfeka kwesimbi.

3.2Mhando dzakasiyana dzehunhu

Kune kunyanya marudzi matatu emarata esimbi asingapfeki: rudzi-chinangwa mhando, rudzi rusingachinji, uye mhando inodzivirira kupisa kwepamusoro.

Iyo general-chinangwa chekupfeka-resistant simbi ndiro ine yakagadzikana kuita uye yakakodzera kune yakajairika kupfeka mamiriro. Iine zvakanaka kupfeka kusagadzikana uye simba rine mwero. Iyo tekinoroji paramita inogona kusanganisira imwe yekuoma nhanho, kazhinji kutenderera 50-60 HRC. Iko kuumbwa kwezvinhu kunowanzo kuve nezvinhu zvakaita sechromium uye manganese kuti uwedzere kupfeka kuramba. Mukuita, inogona kumira imwe dhigirii reabrasion uye inoshandiswa zvakanyanya mumaindasitiri akadai sekugadzira michina.

Iyo inopesana-inodzivirira kupfeka-inodzivirira simbi ndiro yakagadzirirwa kumira zvinorema. Iyo ine yakakwirira kuoma uye yakanakisa kukanganisa kupikisa. Izvo zvinhu zvinowanzo ine alloy zvinhu zvinowedzera kukanganisa kwayo kuramba. Semuyenzaniso, mamwe mahwendefa esimbi asingabatike kupfekwa anogona kuve nekuoma kweanosvika 45-55 HRC asi aine hukuru hwekuramba. Rudzi urwu rwakakodzerwa nekushandisa uko michina iri pasi pekukanganisa kazhinji, senge mumigodhi uye maindasitiri ekuvaka.

Iyo yepamusoro-tembiricha inodzivirira kupfeka-inodzivirira simbi ndiro inogona kushingirira tembiricha yepamusoro. Yakagadzirwa nezvinhu zvakakosha zvealloy zvinogona kuchengetedza kugadzikana pakupisa kwakanyanya. Iyo tekinoroji paramita inogona kusanganisira yakanyanya tembiricha yekushandisa inosvika 800-1200 ° C. Iko kuumbwa kwezvinhu kunowanzo kuve nezvinhu zvakaita senickel uye chromium kuve nechokwadi chepamusoro-tembiricha kuramba. Mukuita, inoshandiswa zvakanyanya munzvimbo dzekupisa kwepamusoro senge vira uye kilns mumaindasitiri emetallurgical uye simende.

Nguva yekutumira: Oct-31-2024