Kupisa Yakakungurutswa Stainless Simbi Plate

Zvinodiwa kuti ugone kumira nekuora kweoxalic acid, sulfuric acid iron sulfate, nitric acid, nitric acid hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid, acetic acid uye mamwe maasidhi. Inoshandiswa zvakanyanya muindasitiri yemakemikari, chikafu, mushonga, kugadzira mapepa, peturu, simba reatomu uye mamwe maindasitiri, pamwe nenzvimbo dzakasiyana dzezvivakwa, kitchenware, tableware, mota uye midziyo yemumba. Kuti ive nechokwadi chekuti michina yemagetsi senge kusimba kwegoho, kusimba kwesimba, kurebesa uye kuomarara kweakasiyana simbi mahwendefa anosangana nezvinodiwa, mahwendefa esimbi anofanirwa kurapwa kupisa senge annealing, kurapwa kwemhinduro uye kurapwa kwekuchembera kusati kwasununguka.

Stainless simbi ndiro ine yakatsetseka pamusoro, yakakwira plastiki, kuoma uye kusimba kwemagetsi, uye inoshingirira mukuora kweasidhi, alkaline gasi, mhinduro uye mamwe midhiya. Imhando yesimbi yealloy isiri nyore kuita ngura, asi haina ngura zvachose.

Kupokana kwekuora kwesimbi isina tsvina kunonyanya kuenderana nekuumbwa kwayo kwealloy (chromium, nickel, titanium, silicon, aluminium, nezvimwewo) uye chimiro chemukati. Chromium inoita basa guru. Chromium ine kugadzikana kwemakemikari yakakwira, inogona kugadzira firimu rekuita pamusoro pesimbi, kutsaura simbi kubva kunze, kudzivirira ndiro yesimbi kubva kune oxidation uye kuwedzera kushora kwesimbi yesimbi. Mushure mekunge iyo passivation firimu yaparadzwa, iyo corrosion resistance inoderera.

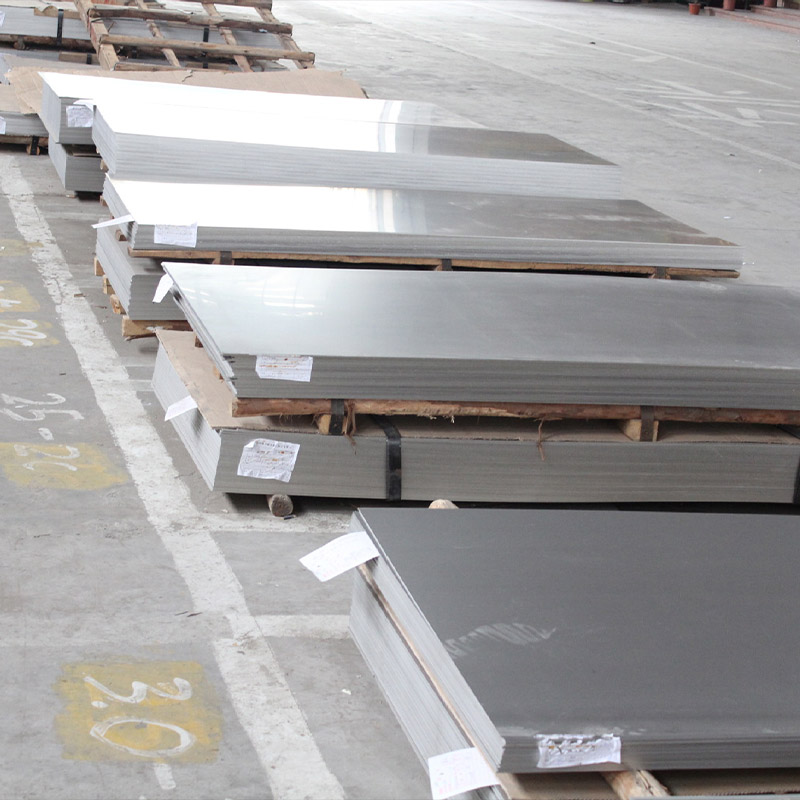

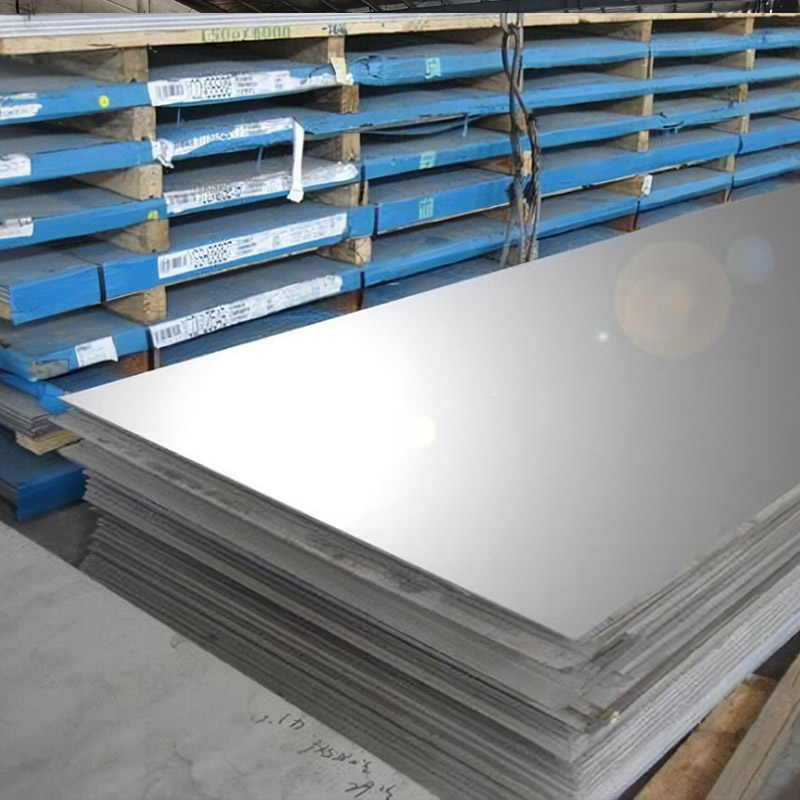

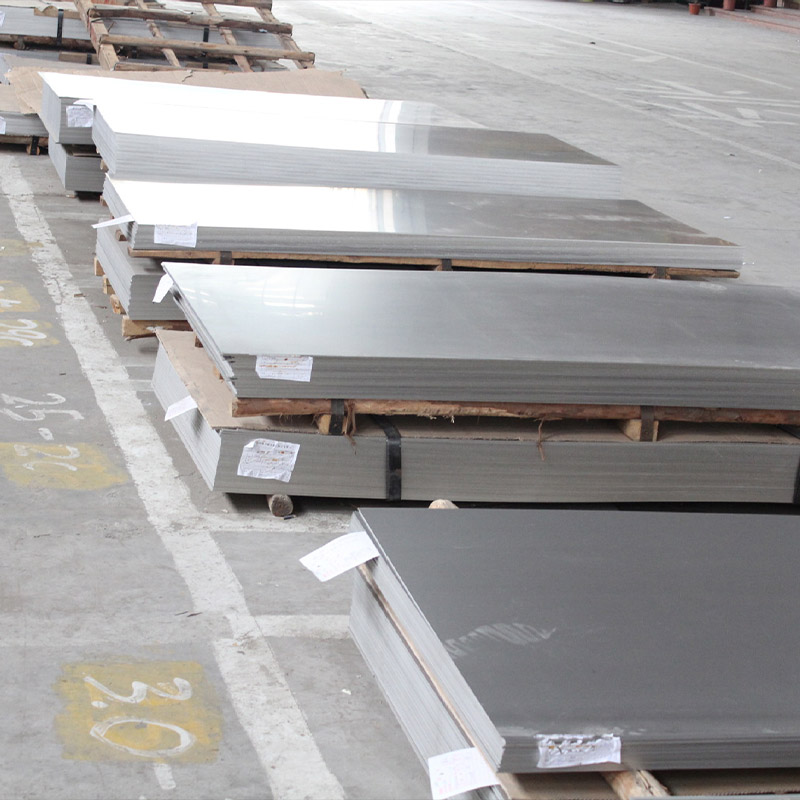

Zvinoenderana nemaitiro ekugadzira, kune marudzi maviri ekudziya kupisa uye kutonhora kukunguruka, kusanganisira ndiro yakatetepa ine ukobvu hwe0.5-4 mm uye gobvu ndiro rine ukobvu hwe4.5-35 mm.

Zvinoenderana nechimiro chechimiro chegiredhi resimbi, inogona kukamurwa kuita 5 mhando: austenite mhando, austenite ferrite mhando, ferrite mhando, martensite mhando uye kunaya kwekuomesa mhando.

Yakakwirira simba resimbi isina simbi ndiro ine yakanakisa corrosion kuramba, kukotama processability uye kuoma kwezvikamu zvewelding, pamwe nekutsikirira processability yewelding zvikamu uye nzira yayo yekugadzira. Kunyanya, ndiro yesimbi isina tsvina ine Si, Mn, P, s, Al uye Ni ine zvakakodzera zviri pasi pe0.02% yeC, isingasviki 0.02% yeN, inopfuura 11% yeCr uye isingasviki 17%, uye kusangana nezvinodiwa zve12 ≤ Cr Mo 1.5si ≤ 17, 1 ≤ Ni 30 (cn) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3mo ≥ 16.0, 0.006 ≤ C n ≤ 0.030 ichapiswa kusvika 850 ~ 1250 ℃, uye ipapo kurapwa kwekupisa kuchaitwa pamwero wekutonhora unopfuura 1. ℃ / s. Neiyi nzira, inogona kuve yakakwira-simba resimbi isina tsvina ndiro ine martensite inodarika 12% nehuwandu, simba rakakwirira rinopfuura 730mpa, kusaita ngura uye kubhenda processability, uye kusimba kwakanyanya kwekupisa kupisa kwakakanganiswa nzvimbo. Kuita kwekutsika kwezvikamu zvakasungwa zvinogona kuvandudzwa zvakanyanya nekushandisa zvakare Mo, B, nezvimwe.