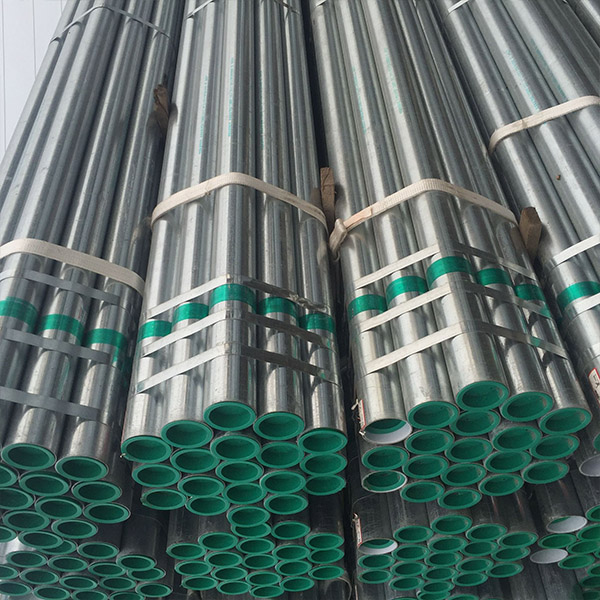

Kupisa Dip Galvanized Steel

Nominal wall ukobvu (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Coefficient parameters (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Cherechedza: Iyo mechanical properties yesimbi indekisi yakakosha kuti ive nechokwadi chekupedzisira kushandiswa kwekushanda (mechanical properties) yesimbi, uye zvinoenderana nemakemikari ekuumbwa kwesimbi uye kupisa kwekupisa. Muyero yesimbi pombi, zvinoenderana nezvinodiwa zvakasiyana zvekushandisa, iyo tensile zvivakwa (tensile simba, goho simba kana goho poindi, kureba),kuomarara uye kuoma indexes kunotsanangurwa, pamwe nepamusoro uye yakaderera tembiricha zvivakwa zvinodiwa nevashandisi.

Simbi mamakisi: Q215A; Q215B; Q235A; Q235B.

Test pressure value/Mpa: D10.2-168.3mm is 3Mpa; D177.8-323.9mm is 5Mpa

Miyero yenyika uye saizi zviyero zvemapaipi emarara

GB/T3091-2015 Welded simbi pombi nokuda yakaderera kumanikidzwa mvura yekufambisa

GB/T13793-2016 Longitudinal yemagetsi welded simbi pombi

GB/T21835-2008 welded simbi pombi saizi uye chikwata kureba uremu

The process flow is:dema chubhu-alkaline washing-mvura washing-pickling-mvura rinsing-kunyorova rubatsiro-kuomesa-hot dip galvanizing-external blowing-internal blowing-air cooling-water cooling -Passivation-water rinsing-inspection-weighing-storage.

Mapombi anogaronzi ane galvanized, mapaipi ane galvanized anoshandiswa kugadzira gasi, uye mhando dzepombi dzesimbi dzinoshandiswa pakudziisa ipombi dzine galvanized. Mapaipi ane galvanized anoshandiswa sepombi dzemvura. Mushure memakore akati wandei ekushandiswa, ngura yakawanda uye tsvina inogadzirwa mumapombi, uye iyo yero mvura inoyerera kunze haingosvibisi ware yehutsanana, uye inosanganiswa nemabhakitiriya anobereka pamadziro emukati asina kuenzana, uye kukora kunokonzera. iyo yakakwirira yesimbi inorema mumvura, iyo inoisa zvakanyanya mungozi hutano hwemuviri wemunhu.

Galvanized simbi pombi yekubatanidza nzira: threaded, welded.

Roll groove connection

(1) Kutsemuka kwe roll groove weld

1. Svedzesa mukati memadziro welding mbabvu dzepressure groove chikamu chenozzle kuderedza kupikisa kwegoro rinokunguruka.

2, Gadzirisa axis yepombi yesimbi uye inotenderedza grooving midziyo, uye inoda kuti pombi yesimbi uye inomonereka girofu midziyo kuti ive nhanho.

3. Rongedza groove yekutsikirira kumhanya, uye groove yekugadzira nguva haigone kudarika chirevo, shandisa simba zvakaenzana uye zvishoma nezvishoma.

(2) Roll groove simbi pombi kuputsika

1. Svetesa mukati memadziro welding mbabvu dzepressure groove chikamu chemuromo wepombi kuti uderedze kupikisa kwegororo.

2, Gadzirisa axis yepombi yesimbi uye inotenderedza grooving midziyo, inoda kuti pombi yesimbi uye inotenderedza grooving midziyo kuti ive nhanho.

3. Rongedza kumhanya kwekudzvanya, kasi yekudzvanya haigone kudarika chirevo, shandisa simba zvakaenzana uye zvishoma nezvishoma.

4. Tarisa hupamhi uye modhi yerutsigiro rwerutsigiro uye pressure roller ye rolling groove midziyo, uye tarisa kana pane kusawirirana muhukuru hwema roller maviri, izvo zvinogona kukonzera kubatwa.

5. Shandisa vernier caliper kuti uone kana groove yepombi yesimbi inotsanangurwa.

(3) Iyo groove yakaumbwa nemuchina wekutenderedza groove inofanirwa kuzadzisa zvinotevera zvinodiwa

1, Nzvimbo yepombi inopera kune chikamu che groove inofanira kuva yakatsetseka uye isina kuenzana uye mabhii.

2, Pakati pe groove inofanira kunge yakatarisana nemadziro epombi, hupamhi uye kudzika kwegorofu kunofanirwa kusangana nezvinodiwa, uye tarisa kana iyo clamp chikamu chemhando chakarurama.

3. Isa lubricant parubha sealing ring uye tarisa kana mhete yekuisa chisimbiso yerabha yakanganiswa. Mafuta haafanire kunge ari mafuta ekuzora.

Welded kubatana

1. Muromo wepombi wepombi yesimbi yakasvibiswa haisi mumutsara wakarurama uye kune dambudziko nemuromo we oblique wepombi yesimbi mushure mekuputika. Inokurudzirwa kugura musoro wepombi kwenguva pfupi isati yagadziriswa.

2, Mushure mekunge galvanized simbi pombi nozzles abatanidzwa, maviri nozzles haana kusimba akabatana, zvichikonzera kusaenzana ukobvu hwejoini yakasungwa; uye pombi ine elliptical nekuda kwezvikonzero zvayo kana mabhambu ekufambisa. Inokurudzirwa kugura musoro wepombi kwenguva pfupi. Process zvakare.

3. Pashure pokunge mhuno dzepombi dzesimbi dzaputirwa, matuzu anooneka pamuromo:

4. Nekuda kwezvikonzero zvehunyanzvi panguva yewelding.

5. Kune zinc nodules mumhino, izvo zvinogona kukonzera kunetsa kwewelding uye blisters. Kana zinc nodules dzakakura uye mapaipi akawandisa, zvinyoro zvinyoro zvezinc zvinofanira kubviswa.

Wire connection

1, Buckle ine Threaded: Iyo pombi hoop uye tambo yakarukwa haigone kubatwa zvachose, kusunungura, cheka chikamu chisina kujairika, uye woisa zvakare shinda.

2. Iyo tambo yepombi yesimbi uye pombi hoop thread haifanani uye haigoni kubatanidzwa. Iyo pombi hoop inofanira kutsiviwa kana kuti midziyo inofanira kugadziriswa uye kudzokorora tambo.

3. Kudhinda kusipo mushure mekunge pombi yesimbi yaiswa shinda: Edza kana ukobvu hwemadziro hwepombi yesimbi huchikwanisa kusangana nehupamhi hunodiwa hwepombi yakarukwa.