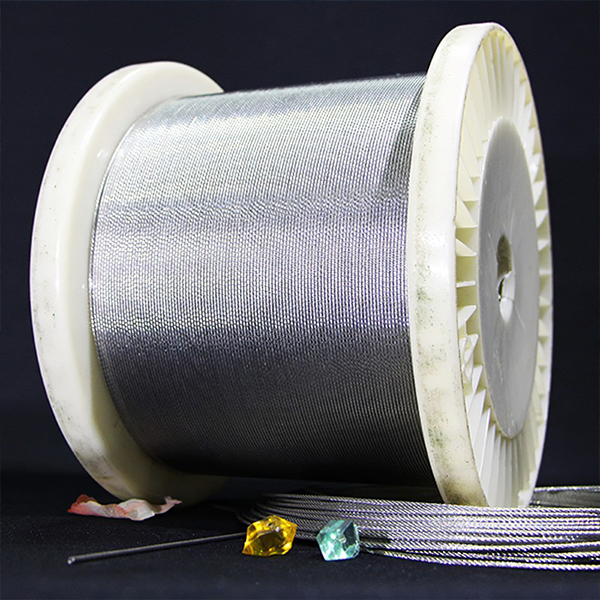

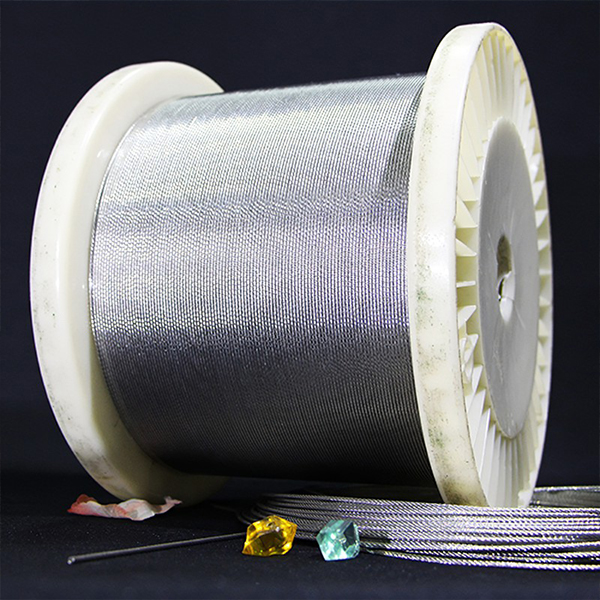

Stainless Steel Rod Ultra Thin Metal Wire

Simbi giredhi: Simbi

Maitiro: AISI, ASTM, BS, DIN, GB, JIS

Mabviro: Tianjin, China

Rudzi: Simbi

Chikumbiro: maindasitiri, kugadzira fasteners, nzungu uye mabhaudhi, nezvimwe

Alloy kana kwete: kwete alloy

Chinangwa chakakosha: simbi yekucheka yakasununguka

Muenzaniso: 200, 300, 400, akatevedzana

Zita rechiratidzo: jinbaicheng

Giredhi: Stainless simbi

Chitupa: ISO C

Zviri mukati (%): ≤ 3% Si zvemukati (%): ≤ 2%

Wire geji: 0.015-6.0mm

Muenzaniso: iripo

Kureba: 500m-2000m / reel

Surface: nzvimbo inopenya

Hunhu: kupikisa kupisa

Stainless steel wire drawing (stainless steel wire drawing): simbi inogadzirwa neplastic process umo tambo yewaya kana waya isina chinhu inotorwa kubva mugomba rewaya yekudhirowa inofa pasi pechiito chesimba rekudhirowa kugadzira simbi ine chikamu chidiki. waya kana waya yesimbi isina ferrous. Waya dzine maumbirwo akasiyana-siyana emuchinjika uye saizi dzesimbi dzakasiyana-siyana uye alloys anogona kugadzirwa nekudhirowa. Waya inodhonzwa ine hukuru chaihwo, nzvimbo yakatsetseka, yakapusa yekudhirowa michina uye mold, uye nyore kugadzira.

Iyo yekushushikana mamiriro ekudhirowa waya ndiyo matatu-dimensional principal stress state yenzira mbiri yekumanikidza kushushikana uye imwe-nzira yekumanikidza kushushikana. Kuenzaniswa neiyo principal stress state uko ese ari matatu mafambiro ari compressive stress, iyo simbi yakadhonzwa waya iri nyore kusvika kune iyo mamiriro epurasitiki deformation. Iyo deformation mamiriro ekudhirowa inzira nhatu huru deformation mamiriro maviri-nzira yekumanikidza deformation uye imwe tensile deformation. Iyi nyika haina kunaka kune plasticity yezvinhu zvesimbi, uye zviri nyore kugadzira uye kufumura kuremara kwepasi. Huwandu hwekupfuura deformation mukuita kwewaya kudhirowa kunogumira nekuchengetedza kwayo chinhu, uye iyo idiki huwandu hwekupfuura deformation, iyo yakanyanya kudhirowa kupfuura. Naizvozvo, mapeji akawanda ekuenderera mberi-kumhanya kudhirowa anowanzoshandiswa mukugadzirwa kwewaya.

| Waya dhayamita (mm) | Xu kushivirira (mm) | Yakanyanya kutsauka dhayamita (mm) |

| 0.020-0.049 | +0.002 -0.001 | 0.001 |

| 0.050-0.074 | ±0.002 | 0.002 |

| 0.075-0.089 | ±0.002 | 0.002 |

| 0.090-0.109 | +0.003 -0.002 | 0.002 |

| 0.110-0.169 | ±0.003 | 0.003 |

| 0.170-0.184 | ±0.004 | 0.004 |

| 0.185-0.199 | ±0.004 | 0.004 |

| 0.-0.299 | ±0.005 | 0.005 |

| 0.300-0.310 | ±0.006 | 0.006 |

| 0.320-0.499 | ±0.006 | 0.006 |

| 0.500-0.599 | ±0.006 | 0.006 |

| 0.600-0.799 | ±0.008 | 0.008 |

| 0.800-0.999 | ±0.008 | 0.008 |

| 1.00-1.20 | ±0.009 | 0.009 |

| 1.20-1.40 | ±0.009 | 0.009 |

| 1.40-1.60 | ±0.010 | 0.010 |

| 1.60-1.80 | ±0.010 | 0.010 |

| 1.80-2.00 | ±0.010 | 0.010 |

| 2.00-2.50 | ±0.012 | 0.012 |

| 2.50-3.00 | ±0.015 | 0.015 |

| 3.00-4.00 | ±0.020 | 0.020 |

| 4.00-5.00 | ±0.020 | 0.020 |

Kazhinji, yakakamurwa kuita 2 akateedzana, 3 akatevedzana, 4 akatevedzana, 5 akatevedzana uye 6 akatevedzana Stainless simbi maererano austenitic, ferritic, nzira mbiri Stainless simbi uye martensitic Stainless simbi.

316 uye 317 Stainless simbi (ona pazasi kune zvimiro zve 317 Stainless simbi) ane molybdenum-ine Stainless simbi. Izvo zviri mumolybdenum mu317 simbi isina tsvina zvakakwirira zvishoma pane izvo zve316 simbi isina tsvina. Nekuda kwe molybdenum musimbi, kuita kwese kwesimbi iyi kuri nani pane 310 uye 304 simbi isina tsvina. Pasi pemamiriro ekushisa kwepamusoro, kana huwandu hwe sulfuric acid huri pasi pe15% uye yakakwirira kudarika 85%, 316 Stainless simbi ine zvakasiyana-siyana zvekushandisa. 316 simbi isina tsvina zvakare ine yakanaka yekupikisa chloride corrosion, saka inowanzo shandiswa munzvimbo dzemugungwa. 316L simbi isina tsvina ine yakanyanya kabhoni yemukati ye0.03, iyo inogona kushandiswa mumashandisirwo apo annealing haigone kuitwa mushure mewelding uye yakanyanya corrosion kuramba inodiwa.